Milwaukee CNC Machining Equipment List

3-Axis Milling

3-Axis milling on a vertical milling machine allows for 2.5D and 3D machining of most parts. Using X, Y, and Z movement 3-axis milling is used for the majority of machining projects. Milling on a 3 Axis machine requires each work face to be machined independently. For each work face the part needs to be positioned and secured in a process called work-holding.

4 & 5-Axis Milling

4 and 5-Axis milling allows for 3D machining with either a rotating part or a rotating mill. Using X, Y, Z, A and possibly B axis 4 and 5 -axis milling is used for complex machining projects. Milling on a 4-5 Axis machine rotates the part for complex contours and shapes.

Turning

Turning on a lathe allows for machining of cylindrical parts. Using X, Y, and A movement lathes are used for nearly all cylindrical machining projects. Turning on a lathe has limitations on the overall diameter of the stock being machined at 7 inches, but can turn parts up to 32 inches in length.

| Type | Brand | Model | Machining Size | Qty |

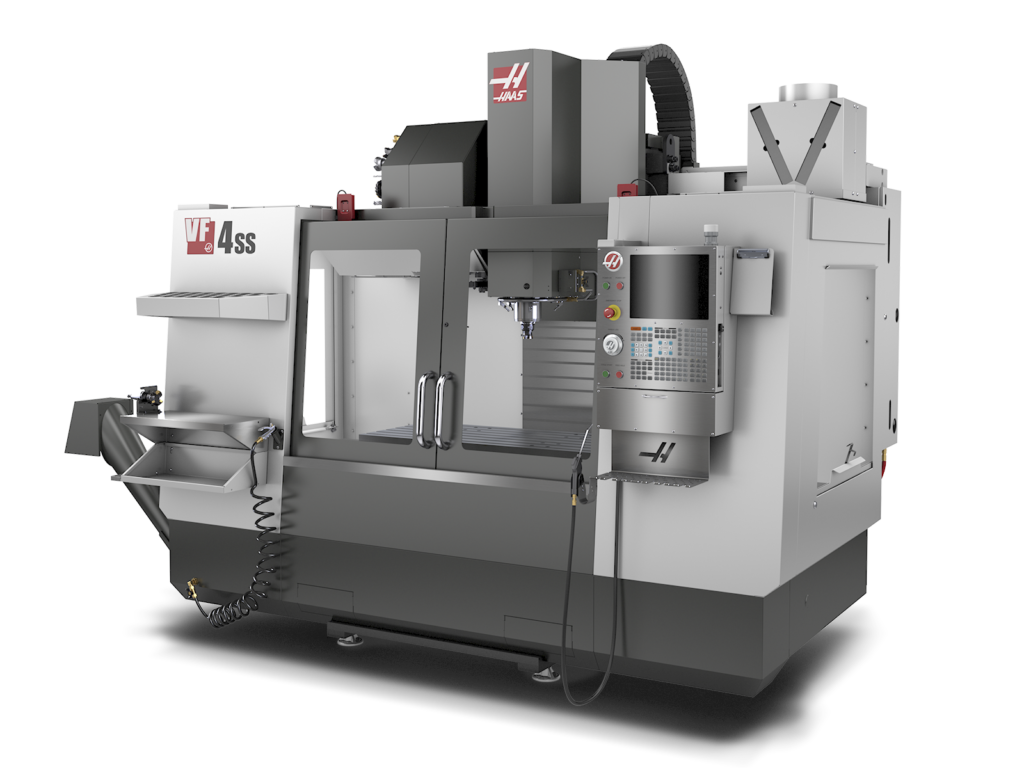

| CNC Machining Center | Haas | VF 4SS | 28”x20”x50” | 1 |

| 5th Axis for VF 4 | 8”x8”x8” | 1 | ||

| CNC Machining Center | Haas | VF 3SSYT | 28”x26”x40” | 1 |

| 5th Axis for 3SSYT | 8”x8”x8” | 1 | ||

| CNC Machining Center | Haas | VF 3 | 40”x20”x25” | 1 |

| 4th Axis for VF 3 | 40”x20”x25” | 1 | ||

| CNC Machining Center | Haas | VF 0E | 30”x16”x20” | 1 |

| 4th Axis for VF 0E | 30”x16”x20” | 1 | ||

| CNC Machining Center | Haas | VF 2SS | 30”x16”x20” | 2 |

| 5th Axis for VF 2 | 10”x10”x10” | 1 | ||

| CNC Machining Center | Haas | DM-2 | 28”x16”x15.5” | 2 |

| 5th Axis for DM-2 | 6”x6”x6” | 1 | ||

| CNC Machining Center | Haas | VF2SSYT | 30”x16”x20” | 2 |

| CNC Machining Center | Tormach | PCNC770 | 14”x7.5”x13.25” | 1 |

| CNC Lathe | Okuma | L250 | 1/8”Ø-3”Ø x 58″ | 1 |

| CNC Lathe | Okuma | L350* | 3”Ø-11”Ø x 13″ | 1 |

| CNC Lathe | Okuma | L300-MYW* | 15”Ø x 18″ | 1 |

| Manual Milling Center | Acer | E-Mill | 9″x42″ | 1 |

| Automated Saw | Berhinger | HBE-261A | 28″ x 26″ | 1 |

| Round 90o | 10.2″ | |||

| Rectangle 90o | 11.8″ x 10.2″ |